What is print resolution?

There are two types of resolution when it comes to 3D printing:

- Horizontal (XY) resolution – the smallest individual element a 3D printer can intentionally create on a two-dimensional scene

- Vertical resolution (layer thickness/height) – the smallest thickness of a layer

The horizontal resolution in SLA printers

Resolution in SLA printers depends on the printing method as well as the used resin (for example higher viscosity of the photopolymer, might lead to the elephant’s foot issue).

SLA printers use UV light to form a 2D image of the model. The building plate sinks in a vat with photopolymer resin, where the curing process takes place. Uncured resin behaves like a viscous fluid. When curing, the chemical structure of the monomer molecules of the resin undergoes chain formation and linear growth through branching (polymerization). The molecule chains crosslink resulting in a large, rigid, three-dimensional molecular network. The final result of this process is a fully cured polymer network, the model.

SLA printers use multiple methods of utilizing the UV light to print the 3D model:

- UV Laser image formation

- Using transparent LCD as a Mask (MSLA)

- High-Resolution Transparent Display

- Continuous Liquid Interface Production

- DLP Light Projector

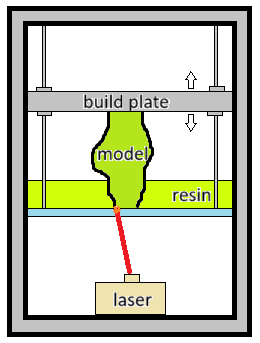

UV Laser Image Formation

In this method, a UV laser is used to cure desired points to make a 2D image on the bed. The approach uses two motorized mirrors that move the laser pointer. The UV light exposes the resin through a glass window, where the part of the resin becomes solid on the building plate. After creating the 2D layer, the bed moves up a required height to let the uncured resin fill out the space between the building layer and the glass window. Then the process repeats.

Resolution is indicated by the UV laser light diameter.

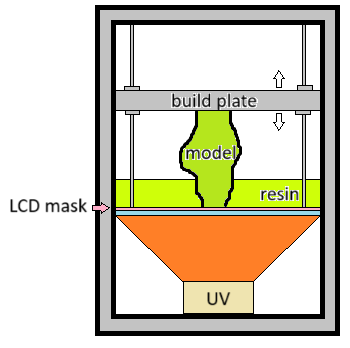

Transparent LCD MASK – most commonly used, supported in Lychee Slicer

In this method, a transparent LCD mask is used above the UV light, which lights up the whole glass window. The LCD mask creates an image, which masks the area that should not be exposed to the light. Light goes only through the not-activated pixels on the LCD mask, and that is the area where the resin cures in the defined layer. After creating the 2D layer, the bed moves up to let the uncured resin fill out the space between the building layer and the glass window, and after it positions itself on a required height. Then the process repeats. In this approach, a whole 2D image is cured at once.

Resolution is indicated by the pixel size of the LCD mask.

High-Resolution Transparent Display

This approach is the same as the transparent LCD mask, except the used LCD is a high-resolution display, that allows printing very detailed models. The high-resolution LCD panels are costly.

Resolution – the pixel size of the LCD mask.

Continuous Liquid Interface Method

Unlike the transparent LCD mask printer, this approach doesn’t require the build platform to move up and down for the resin to fill the space in between creating the layers. An additional membrane is placed on the LCD mask, allowing the resin to instantly fill the space between the LCD and the build platform when the build platform increases its height. This process saves time and increases printing speed.

Resolution is indicated by the pixel size of the LCD mask.

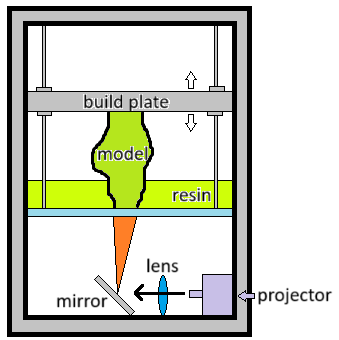

DLP Resin Printing

DLP resin printing is similar to the above. Instead of using masking, it uses a high-resolution light projector that flashes UV light into a layer of resin. The light projector is composed of mirrors, lenses, and a digital micromirror device (DMD) on a microchip. The UV light is directed by the mirrors in the shape of one cross-section of the 3D model to the resin. Selected tiny mirrors can be switched off or on, which allows the light to cure selected parts of the resin. Each square-shaped mirror represents one pixel of the projected image.

The resolution depends on the mirror size and the distance between the projector and the resin. Some printers enable the user to change this distance. Increasing the distance causes a reduction in the level of detail that can be achieved.

The vertical resolution in SLA printers

The fundamental of the vertical resolution in SLA printers is the resin used and how it cures. One of the parameters of the resin is its color, as it affects the curing time. Another factor is the set layer thickness. The thinner the layer, the higher the resolution, but also the longer the printing time.

Last updated on